| Author |

Message |

Fabio

Tinkerer

Username: Fabio

Post Number: 4

Registered: 09-2009

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, October 08, 2009 - 02:22 am: |

|

I have some problems with a Zorki-4 at slow speeds. The camera I got had misplaced slow speed system: the pin below the ring went past its (1/60) position preventing the preset of "B" and 1/30 speeds. I disassembled the slow speed block, cleaned and lubricated everything and, now, high speeds, B and 1/30 (that behaved like B...) seems good and reliable.

Now the problem: slow speed subassy works good, the pawl seems to position correctly but:

-A- when slow speeds are selected (eg 1/8) the 2nd curtain hits the pawl and wait (correctly) but the pawl get "stuck" and cannot be retracted: I have to "push" the slow speed ring to give it the "extra torque" to free the 2nd curtain arm.

-B- when winding, with a low speed engaged, the pawl gets "in the way" of the 2nd curtain arm that can't be winded to final position: I would expect that, as the pawl seems in its correct position, the 2nd curtain arm should push it back (pawl is tapered, suggesting it).

It seems that the pawl shows quite a big reaction to move: this would probably cause both incorrect behaviours.

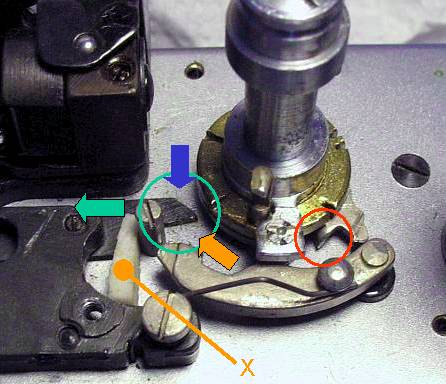

I attach a detail of the system (slow speed subassy escapment has been removed): green circle shows the pawl (it is in retracted position thanks to a small eraser chip (X) I inserted to use high speeds); red circle is the 2nd curtain arm. Blue arrow shows direction were 2nd curtain arm hits the pawl when winding; orange arrow shows position were the arm "waits" till escapement (should) free it.

Can someone confirm that it should be working in this way and I just have a "too stiff" movement of pawl?

Rick Oleson's schematics and notes (http://rick_oleson.tripod.com/index-131.html and http://rick_oleson.tripod.com/index-58.html)were very useful to understand the system. Also found this document ( http://thephotocollege.com/Zorki%204_4K%20CLA%20Fin.pdf ) very useful.

Many thanks to all!!!

Fabio |

Fabio

Tinkerer

Username: Fabio

Post Number: 5

Registered: 09-2009

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, October 09, 2009 - 03:22 am: |

|

Update: I think I have partially solved the problem.

I re-cleaned and re-lubricated the pawl; now, when winding, it can be moved back by the 2nd curtain lever and the escapment has enough force to retract it while the 2nd curtain is pushing on it waiting for its release.

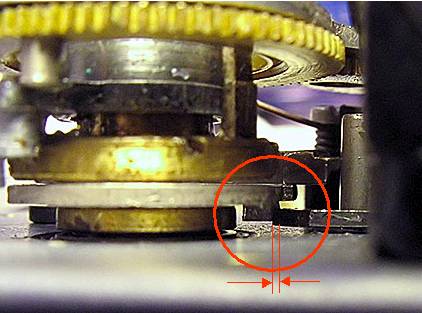

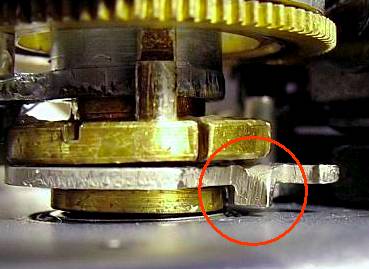

Unfortunately what happens now is that often (usually 3 out of 5 times) the pawl is pushed back immediately by the action of the 2nd curtain arm when it hits the pawl. I cleaned the tip of the pawl (removed any oil trace) and the arm to increase the "sticking" but what seems is that the pawl engages the arm just on its very tip (see image). The 2nd curtain arm seems not "rounded" or damaged (image); the pawl tip, too, seems "good".

From the eterogeneous experience in this kind of mechanisms can anyone suggest if the amount of overlap between pawl and arm is appropriate for the function? There is no possible adjustment for the pawl position: I am afraid that one should file the edge of the pawl that rest on the stroke stop.

I will try also to adjust the curtain spring tension: it is possible that someone increased it to compensate for the old lubrication and that, now, with new cleaning and lubrication the 2nd curtain pushes to heavily to the pawl?

Thanks to all for your notes/suggestions.

Fabio

amount of overlap between pawl and 2nd curtain arm:

2nd curtain arm:

|

|