| Author |

Message |

Der_uli

Tinkerer

Username: Der_uli

Post Number: 16

Registered: 05-2010

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, November 12, 2010 - 08:44 am: |

|

Here’s my report on repairing the film advance gear of an old camera. I won’t tell you which camera model it is – it would be too modern for this forum. Connoisseurs will determine it from the pictures. But I think the story is a help for similar problems with little cogs in other cameras.

When I got this camera, everything but the film counter seemed to work. The film wasn’t advanced. Since it was from a very reputed manufacturer, I phoned their service department. They told me literally, "This is yet an *analog* camera. For those, there is no service anymore." So I had to fix the problem myself.

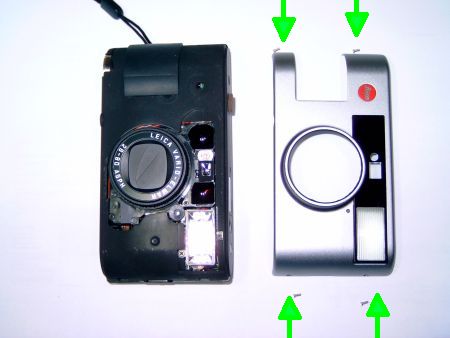

First step was to open the camera by taking out all those #00 screws marked green:

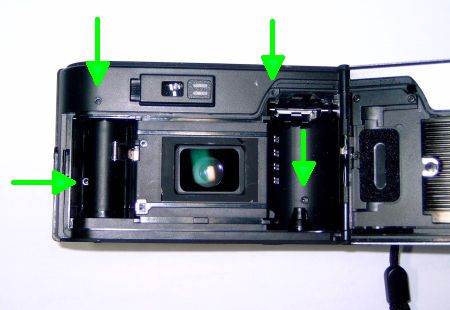

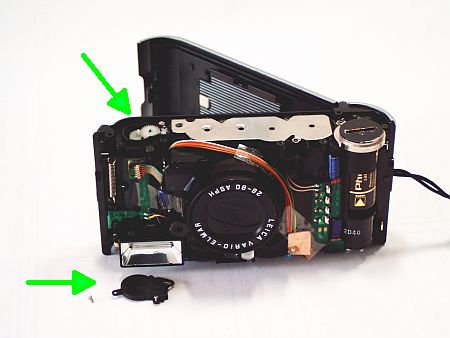

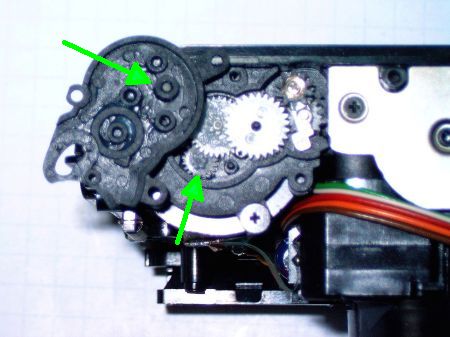

The gearbox is on the bottom:

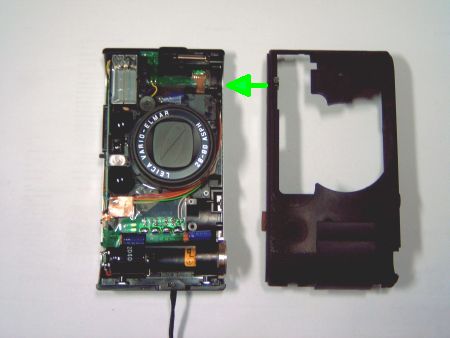

A closer inspection with a magnifier revealed that the shaft of one sprocket was broken. Part of it stuck in the top cover.

The little six- toothed cog itself was worn. As it built a unit together with another bigger cog, I had to replace both.

I measured the axle diameter to 0.8 mm, the outer diameter of the six teeth sprocket was 1.4 mm, the big one had 4.5 mm. I counted it three times, with the help of a magnifier, to have 19 teeth. So their modulus, diameter divided by number of teeth, was around 0.235. A strange Chinese standard, maybe?

A wealth of such little parts can be found at www.mikroantriebe.de for European customers. In the US, try: http://www.smallparts.com/

http://www.microfasteners.com/

http://www.acecam.com/camera-parts-sources.html

The closest approximation to my measurements was available with modulus 0.25. But these parts are a little bigger. So I ordered not only a 19 teeth cog, but a 17 teeth one too. Its outer diameter resembled more closely the original one. It would result in a 12% difference in speed during film transport, which is negligible.

Common to all those new gears was a 0.6 mm diameter inner hole. I found a sewing needle with exactly this size. To fit to the 0.8 mm original axle, I got a short piece of 0.6 mm inner / 0.8 mm outer diameter brass tube from a local model-craft shop. The other parts arrived within a week.

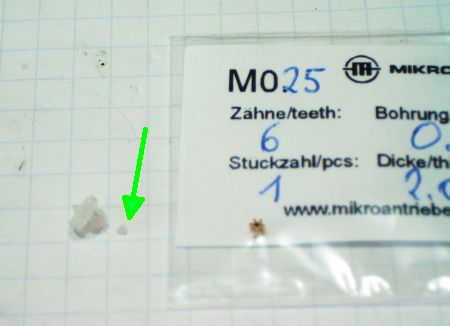

This picture of the old and new six-teeth cogs shows the size difference:

But when I compared the 17- and 19-teeth ones, I realized that the original had 18 teeth! Aarrghh, I counted it wrong. It had exactly modulus 0,25, just as the six-teeth one, which was smaller only due to wear!!

So I decided to re-use the old 18 teeth cog by cutting off the 6-teeth one. The only difficulty was to keep the new 0.6 mm hole exactly centered.

After sliding everything on the needle shaft, it looks like this:

A small tilting error was corrected by heating up the needle with a soldering iron and letting it cool down with the sprocket in correct position. Finally I put on two small lengths of the 0.6/0.8 mm tube. A very little cyanacrylate glue secured all parts. After drying, the overall length was ground to size.

The whole assembly can now be cleaned and put back in the gear box, together with some grease.

Reassembly of the camera body is straightforward. Only take care of the little rubber knob marked green in the picture.

Now the camera is fit again for some rolls of film... some pictures taken with it are shown here:

|

Ethostech

Tinkerer

Username: Ethostech

Post Number: 166

Registered: 07-2006

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, November 13, 2010 - 02:23 am: |

|

Pardon my gasp - but is that a Leica copy from Outer Mongolia -or a genuine Leica item ? |

Hanskerensky

Tinkerer

Username: Hanskerensky

Post Number: 63

Registered: 05-2009

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, November 13, 2010 - 07:02 am: |

|

Thanks for this usefull information Uli !

btw Like your webpage about the Collimation ! |

Paul_ron

Tinkerer

Username: Paul_ron

Post Number: 227

Registered: 07-2006

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, November 13, 2010 - 08:29 am: |

|

Nice job. It's so hard to work such small plastic and you made it work. Congrats, you are a master craftsman. |

Msiegel

Tinkerer

Username: Msiegel

Post Number: 205

Registered: 03-2008

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, November 14, 2010 - 10:19 am: |

|

Ethostech: Looks like a Leica C3 to me.

Uli:

Very elegant work indeed - respect! |

|