| Author |

Message |

Silvertree

Tinkerer

Username: Silvertree

Post Number: 1

Registered: 05-2012

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, May 09, 2012 - 01:22 pm: |

|

I have been doing some reading here:

https://kyp.hauslendale.com/classics/forum/messages/2/19545.html

I'll quote this line

"3. Set the Speed Wheel to B-3200ISO. This is the setting which should ALWAYS ALWAYS ALWAYS be used when installing or taking off the speed wheel. If I had used this setting a few days ago when disassembling the speed ring, my tungsten wire would not have snapped in the first place. Using any other setting, especially the fast settings like 1/1000-25 would make the disk as tightly wound as possible, just waiting to violently un-spin."

Now I'll confess that I did this the wrong way.

Obviously I had no idea what I was doing when I started. The top nut on the camera was loose and I was cleaning the camera and saw an opportunity to get at some more crevices. I think curiosity also killed this cat. So I removed this white plastic piece I had no business removing and instantly knew I did something wrong when I heard the *PING*! of something releasing.

The light meter stopped working.

Based on my readings of that old post I expect I know what I have done. I'm not a novice but I am entirely new to this particular field of camera repair and now I'm extra cautious.

I have the repair manual as linked in that discussion but the images are heart breakingly awful.

What I want to know specifically is about this little white dial. It appears to have a very tiny coil embedded in it and I am almost certain I broke that connection when the *PING* occurred.

Am I right? Do I need to replace this white disk and possibly whatever it was attached to [functional resistor?]? Is that part freely available? Is the part any cheaper than another camera from Ebay? Does anybody want to jump in and try to give me a step by step repair guide? Based on that forum I think I'll need to replace the tungsten wire, as well, but I haven't opened the top because I'm scared of more time bombs going off.

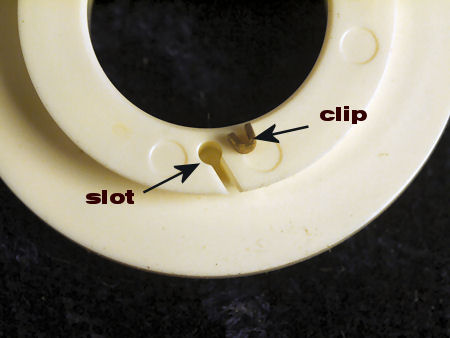

I'll include an image of the white disk in question.

http://img856.imageshack.us/img856/4153/imgp4840edit.jpg

I would really appreciate your help with this matter. Thank you, for reading. |

Brcamera

Tinkerer

Username: Brcamera

Post Number: 174

Registered: 08-2010

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, May 09, 2012 - 09:41 pm: |

|

The white disk does not have a coil embedded in it - this disk just couples the tungsten wire to the resistor that is on the other side of the camera under the rewind knob and moves the resistor according to the shutter speed and ASA that is set. What you might think is a coil is just the small brass keeper that holds the end of the tungsten wire in place. From your photos, I can see that the wire is broken off from the white dial so you will have to remove the top cover and replace the tungsten wire at this point.

Bill |

Silvertree

Tinkerer

Username: Silvertree

Post Number: 2

Registered: 05-2012

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, May 10, 2012 - 07:28 am: |

|

Oh, I get it, the tungsten wire spools around the white disk.

That's encouraging news, thanks, Bill.

I don't feel so anxious about it. |

Fiftyfifty

Tinkerer

Username: Fiftyfifty

Post Number: 56

Registered: 07-2006

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, May 11, 2012 - 01:18 am: |

|

May I put in my idea for you.

1st remove the top, then you will be able to see the route the tungsten wire takes.NOW take a good look on how the wire is attached at the rewind end.

2nd the wire does not go around the white disk, it is only attached to it.

3rd obtain some tungsten wire, looking at your photo, you may be able to use the existing wire,if you can attach the broken end to the white disk, there may be enough wire at the rewind end to allow this.

4th If you the wire is not long enough, and you can not get the correct wire. Get some "Spiderwire or Dandyline " from you local fishing equipment shop, they my even give you a couple of feet free if you explain what it is for.

5th Attach the wire to the white disk,put it back on its pivot and feed the wire around the rollers.Replace the speed dial on and set it to "B" and 3200ASA.The brassdisk at the rewind end has to be tensioned, turn it anti-clockwiseabout 1 1/2 times, holding that, wrap the wire aroun the disk clockwise one complete turn, and then feed it throu the channel in the brass around the screw and secure it to the mounting.

6th Now check the movement by turning the speed dial up to 1/1000 and then to 12 ASA, you will/may have to adjust the length of the wire.

Now checkthe route of the wire is not binding anywhere.

There is a brass screw on the disk at the rewind end which is used to give you some minor adjustment, check the readings against a good lightmeter,this is best done with the top back on.

Hope this helps, it does go on a bit, but in practise it is not that hard.

Doug |

Silvertree

Tinkerer

Username: Silvertree

Post Number: 3

Registered: 05-2012

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, May 13, 2012 - 07:38 am: |

|

Thanks, Doug. That's some very constructive advice.

I will give it all a look and keep my fingers crossed.

I am a bit perplexed as to how I'll actually re-attach the line to the white disk since the connection is so, so tiny but I know it has been done before and I know I'll find a way to make it work.

I haven't opened it up yet but I'll find the time over the week and I'll let you know how I do.

Thanks, again, guys!

-John P |

Brcamera

Tinkerer

Username: Brcamera

Post Number: 176

Registered: 08-2010

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, May 13, 2012 - 12:10 pm: |

|

John,

I have attached a photo showing a close up view of the slot on the pulley and the small brass clip that is used to hold the end of the tungsten wire into the slot. I always use a new pulley and clip although you can remove the old clip and wire end with a bit of work. My procedure is to tie a small knot on the end of the wire and then push it into the slot on the pulley. Then I carefully press the clip into the slot to hold the knot in place (I also use a very small dot of sealer). I've done hundreds of these and never had any later problems..

Bill |

|