| Author |

Message |

Deafburglar

Tinkerer

Username: Deafburglar

Post Number: 1

Registered: 05-2012

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, May 08, 2012 - 12:24 am: |

|

Hi! I am new here and i want some advice on the tool needed to unscrew the self timer lever from an old defunct Konica C35, so that i can use it on a fresh one i bought which has lost the self timer lever (unscrewed, not broken). I think this type of screw is called spanner screw (has the two holes instead of the regular grooves) but i don't know how the respective tool is called so i can look it up on eBay or Amazon ("spanner screwdriver" didn't work). Apart from getting the special tool, is there a DIY way of getting the job done? I would also like to replace the covering on some other cameras, so i may have to remove more than one self timer lever!

Thanks,

Christos |

Glenn

Tinkerer

Username: Glenn

Post Number: 993

Registered: 07-2006

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, May 08, 2012 - 03:28 am: |

|

You can grind down the jaws of a cheap pair of needle nosed pliers, but the easiest and best method to avoid buggering up the pin holes is as follows.

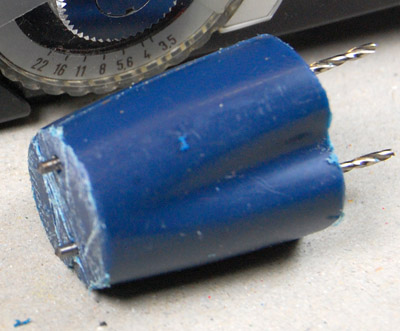

Get yourself a couple of small drill bits that fit the pin holes - ie 1mm or 1.5mm and then snap off the shanks so that you have two pieces steel approx 12/15mm long. Stick a thick piece of adhesive tape over the head of the screw and then push the pieces of shank into the pin holes. The tape will support the two 'pins' you have made and also make sure that you do not place the broken ends of the drill shank into the holes. Now take a cylinder of epoxy putty about 20mm in diameter and 40mm long and push it over the 'pins' right down to the adhesive tape. Leave to set and then pull the tool of the lever assembly - you will now have a tool that will remove the screw and more importantly will not allow you to torque up the screw so tight that you strip the head off - a danger when you go down the plier route.

You use drill bits because you need a high tensile metal to produce the pins, but if you are a modeller then another source of metal would be 'piano wire' sold by many model shops. This is a 'spring' wire and does not bend easily. |

Msiegel

Tinkerer

Username: Msiegel

Post Number: 286

Registered: 03-2008

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, May 08, 2012 - 04:38 am: |

|

You might be looking for something like this:

http://www.amazon.com/Spanner-Wrench-Stainless-Pointed-Slotted/dp/B004WLMIBW/ref =pd_cp_hi_0

But I have to admit it's on the expensive side if you just want to open that one screw.

Another possibility would be looking for those so called "Security Bit Sets" that have bits fitting those more uncommon screw heads:

http://www.amazon.com/SE-pc-Security-Bit-Set/dp/B0009U6AB4/ref=pd_sim_sbs_hi_1

These bits should also be available from a local hardware store.

There are also DIY solutions to making such a tool as already described. Simplest would be two pieces of wire (e.g. off a strong paperclip) held with flat pliers. You can also try to file a straight screw driver blade into shape. Note that those solutions might lead to scratching the screw head or do other dmage to the screw.

If you are planning to do more camera repair proper tools are of course the best solution.

Also have a look at the Micro Tools website

http://www.micro-tools.com/

Search for "spanner" in their store.

Best regards

Martin |

Br1078lum

Tinkerer

Username: Br1078lum

Post Number: 303

Registered: 11-2010

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, May 08, 2012 - 10:22 am: |

|

I use a pair of pin pliers, made for removing C type split washers. You can see them in my set of photos of a C35 Automatic repair I did for a friend. http://flic.kr/s/aHsjyQ4QrZ

PF |

Hollenbj

Tinkerer

Username: Hollenbj

Post Number: 47

Registered: 03-2012

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, May 08, 2012 - 12:04 pm: |

|

I've used almost all the above methods (haven't made an epoxy handle, but sounds good). If I don't have the correct tool already, I favor creating a quality tool that can be used again. The spanner wrenches from MicroTools are worth the investment, but don't always work -- some pin face screws have really small holes. The pin pliers are a good approach. You might need to grind the tips to very small points; grind slowly with frequent quenching oil baths, it'll help retain some of the metal hardness. If you're hand filing the points, perhaps not enough heat generated to worry about baths? Someone here will know.

Whatever you do, don't try to make a tool work when it clearly wants to slip out or do something unwieldy. You *will* ruin your piece. Believe me, I know.

BTW, that's a nice photoessay from Br1078lum. I'll have to refer to it if my C35 ever needs attention. |

Deafburglar

Tinkerer

Username: Deafburglar

Post Number: 2

Registered: 05-2012

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, May 09, 2012 - 02:54 am: |

|

Thanks to everyone! The wrench tool from amazon looks the proper thing to have, but is rather expensive. I already tried two 1mm-thick drill bits held together with a plier, but the screw is too small and too near the lens barrel, i already scratched the surface a bit trying, so i quit that. The security set from Amazon is cheap, but who knows the accurate diameter of these spanner heads? I will consider the spanner wrench, as i am planning at least 3 camera re-covers and it may prove a worthy investment. (Resell it with a generous discount here later when i'm done? Ha ha ha) |

Glenn

Tinkerer

Username: Glenn

Post Number: 995

Registered: 07-2006

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, May 10, 2012 - 09:27 am: |

|

Quite frankly when it comes to removing the small pin 'headed' screws found on cameras, the 'professional', and invariably expensive, tool shop items are a complete waste of money - unless you have a need for this type of tool to remove lens rings and other retaining rings found on lenses and camera bodies, forget it and make your own tool.

My method produces a tool that cannot slip out, always presents the pins at 90 degs to the screw head and having round pins cannot mar the circumference of the locating holes. Nothing looks worse than this type of screw with the pin holes all chewed up to buggery. In my tool the base of the epoxy handle is held in physical contact with the face of the screw head as you push the tool into the screw whilst applying the turning moment. Tool cannot wobble, the pins are a nice snug fit in the holes which means the screw is removed completely unmarked. |

Hollenbj

Tinkerer

Username: Hollenbj

Post Number: 48

Registered: 03-2012

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, May 10, 2012 - 12:56 pm: |

|

Glenn is convincing. I'm going to try his idea.

He's also right about the practicality of making your own tools. I have a spanner wrench, but the tips I have are only good for some (only some) lens disassembly. For your problem, I'd make a tool. Having looked at my C35, I think I'd grind an old screwdriver to a couple points, exactly the distance apart and prong size necessary for this job. I buy old screwdrivers at the local thrift stores for next to nothing and keep a supply in the shop for just this kind of thing. Do you have a Dremel (or generic)? |

Railcrew

Tinkerer

Username: Railcrew

Post Number: 19

Registered: 03-2012

Rating: N/A

Votes: 0 (Vote!) | | Posted on Thursday, May 10, 2012 - 08:50 pm: |

|

Go to wal-mart or any store that has a decent supply of womens make-up, fingernail polish etc... look in the tweezers section. I got a pair of tweezers I stole from my wife that are pointed (not the chisel point like most) they are strong (don't twist as you use them) fit every hole I've come across, instant adjustable, to a certain point of course, probably a 3/4"-1" max on spacing of the holes but they work great. |

Bobd

Tinkerer

Username: Bobd

Post Number: 5

Registered: 01-2007

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, May 11, 2012 - 01:33 pm: |

|

I often use 2 needles held with vice grip pliers. |

Paul_ron

Tinkerer

Username: Paul_ron

Post Number: 285

Registered: 07-2006

Rating: N/A

Votes: 0 (Vote!) | | Posted on Wednesday, May 16, 2012 - 04:58 pm: |

|

you can buy a spanner for that span if you go to Home Depot n get a security screw driver set that includes small 2 pin spanners, hex n torx driver bits meant to be used by carpenters n the trades.

The best DIY alternative, I have used for years, for small spanners such as your little lever is the tip of a small scisors you cnq find em in the makeup section of Rite Aid stores.

For larger spanners I use a C clip pliers that has interchangeable pins which I replaced with hardened steel pins to suit my holes of various sizes. These pliers come in several different configurations n sizes. Some close when gripped some open, some have locking pivots which I like best.

. |

M_currie

Tinkerer

Username: M_currie

Post Number: 291

Registered: 07-2006

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, May 18, 2012 - 07:41 am: |

|

First post in a couple of weeks owing to post bike accident brain damage and vision disturbance, but....

If you're patient, consider taking a cheap asian wrench socket and filing or machining the ends to make a dedicated spanner for small bolts. It can take a while,l but a mid range socket not very good for bolts will often prove stong enough for this, and you'll have a custom socket for life. I did this for the screw ona Nikon PC lens, very successful. I kee- a while bucket of old sockets handy so I can make any dedicated tool within a certain range with time, a hacksaw and a sharp file.

MC |

Paul_ron

Tinkerer

Username: Paul_ron

Post Number: 286

Registered: 07-2006

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, May 21, 2012 - 07:17 am: |

|

Sorry to hear about your bike accident, glad you are alright. Were you wearing a helmet?

The socket idea will make a nice tool, great idea to keep in mind next time I need to custom make a wrench. we all have those cheapo socket sets stuck in our garage somewhere.

Hope your recovery goes well. |

Scott

Tinkerer

Username: Scott

Post Number: 182

Registered: 07-2006

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, May 21, 2012 - 08:05 am: |

|

If you have a Hobby Lobby store nearby, they have tools in the jewelry-making section that look like the ring-clip pliers for removing C-clips. They work on these pin-faced screws.

Otherwise, check the specialy tool shops (where the professional auto mechanics and electricians buy tools). Bring your camera with you to show the people there what kind of tool you need. |

Fedupwithdigital

Tinkerer

Username: Fedupwithdigital

Post Number: 11

Registered: 07-2011

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, June 16, 2012 - 08:14 am: |

|

Just thought I'd add my tuppence worth.

I use old Air Ministry steel engineers spring calipers that my wife's grandfather used as an RAF aircraft fitter in WW2. You can adjust the gap between the legs and, although there is a bit of flex when you twist, as long as I'm careful I've removed self-timer lever screws, winder arm screws and even lens rings without mishap.

A modern equivalent is here - http://www.rdgtools.co.uk/acatalog/Spring_Calipers.html - scroll down to the spring calliper set and the one on the left with the straight points is what I'm on about. |

Hanskerensky

Tinkerer

Username: Hanskerensky

Post Number: 195

Registered: 05-2009

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, June 17, 2012 - 11:09 am: |

|

I partly followed up Glens method and also used drillbits. But instead of epoxy i used a cut away part of the handle of an old throw-away screwdriver. Transfered the locations of the holes by marking them on a piece of masking tape and glued that to the cut handle. Then used the drillbits to actualy drill the holes through the handle.

Works like a charm.

|

Glenn

Tinkerer

Username: Glenn

Post Number: 1023

Registered: 07-2006

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, June 17, 2012 - 02:25 pm: |

|

Nice one Hans - and the drill bits live for another job, which is always useful if you don't have boxes of small diameter bits stashed all over the work shop.I do via an auction of bankrupt stock many years ago, hence my wasteful and extravagant method. Got to use the little buggers up some how! |