| Author |

Message |

Pothman

Tinkerer

Username: Pothman

Post Number: 1

Registered: 05-2012

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, May 01, 2012 - 08:57 pm: |

|

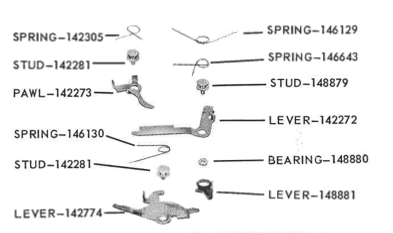

Looking for a spring for a kodak pony IV its part number 142305. Its a little torsion spring. I do not want to have to sacrifice another camera for one tiny spring so any other source would be good or even a way to make one |

Mr_flibble

Tinkerer

Username: Mr_flibble

Post Number: 83

Registered: 10-2011

Rating: N/A

Votes: 0 (Vote!) | | Posted on Monday, September 10, 2012 - 03:04 am: |

|

Get some piano or music wire; a steel high E guitar string is what I used to repair the broken spring in my Ikoflex III. Bend it into shape and then harden it. |

Hi_country_flash

Tinkerer

Username: Hi_country_flash

Post Number: 7

Registered: 12-2012

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, February 19, 2013 - 12:31 am: |

|

It is amazing how many things guitar strings are good for! I use them for piping and hand rails on brass HO locomotives I build. They are much smaller and stronger than the smallest brass rod (.020) you can get , guitar strings get down to about .005 and are tough! The heavy wrapped strings make great "glad hand " type air hose connectors on locomotives too. |

Denny

Tinkerer

Username: Denny

Post Number: 135

Registered: 08-2009

Rating: N/A

Votes: 0 (Vote!) | | Posted on Tuesday, February 19, 2013 - 06:17 pm: |

|

Do you harden it by heating and quenching in water or oil?

Thanks |

Nickon51

Tinkerer

Username: Nickon51

Post Number: 156

Registered: 05-2008

Rating: N/A

Votes: 0 (Vote!) | | Posted on Friday, February 22, 2013 - 07:35 pm: |

|

You should google for hardening, it will give you a better idea than I can.

Basically, you heat the spring to cherry red and then drop it into water. To heat it evenly, place it on a tray covered in a small layer of sand. Heat the tray from underneath until the whole spring is an even cherry red, then slide the the spring and sand off into a container of water waiting nearby. The spring will now be hard and brittle so you need to temper it.

Polish the spring up and repeat the same proceedure but only heat to a straw colour, quench in water the same way.

Should be good to go.

For more info, have a look at some of the clock repair sites about making steel springs. Personally I would try the E string first without hardening. A Banjo B string is a bit thinner than a standard E string.

Good Luck

Greg Nixon |

Denverdad

Tinkerer

Username: Denverdad

Post Number: 28

Registered: 05-2011

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, February 23, 2013 - 04:18 pm: |

|

I have made a number of replacement torsion springs myself using music/piano wire. This site is a good reference for how to do it, and is in fact how I learned.

It is arguable how important the heat treatment step is. Personally I have never gone to the trouble and all my springs continue to operate fine (so far at least!). |

Nickon51

Tinkerer

Username: Nickon51

Post Number: 159

Registered: 05-2008

Rating: N/A

Votes: 0 (Vote!) | | Posted on Saturday, February 23, 2013 - 09:55 pm: |

|

Thats a good link Denverdad. I've bookmarked it for future ref. I agree with your comments about heat treatment of music wires. I think I would wind it first and see what it does. Its only 1 1/4 turns, but much finer than the thinnest piano wire.

Cheers |

Denverdad

Tinkerer

Username: Denverdad

Post Number: 29

Registered: 05-2011

Rating: N/A

Votes: 0 (Vote!) | | Posted on Sunday, February 24, 2013 - 11:00 am: |

|

So far I haven't needed to replace any of those really fine springs. My usual source - eBay seller howardpianoind (who by the way, has a pretty reasonable price for 10-ft lengths I would say) - has sizes down to number "0" which is .009-inch diameter. I wonder if the .005" guitar string that Hi_country_flash mentioned would be about the right size?

Incidentally, I wonder if the OP ever found/made a replacement? It's been about 10 months and we haven't heard back from him. Regardless, it is still a worthwhile discussion I would say.

Jeff |